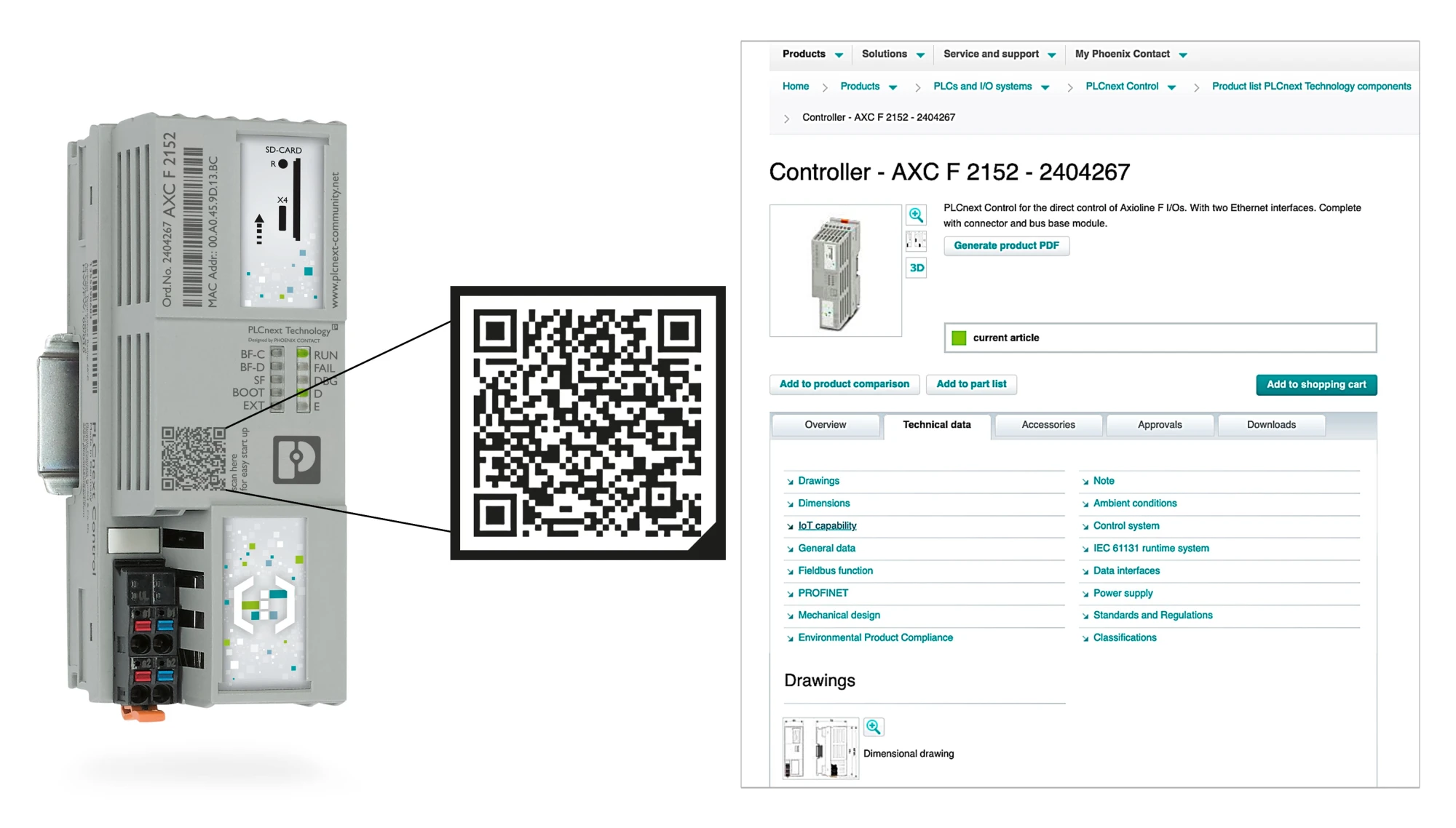

AutomationML – the future of automation

Find out about the possibilities of automation in control cabinet building with AutomationML. In our “AutomationML” knowledge area, we provide you with in-depth insights and practical information. Find out how AutomationML optimizes processes, increases efficiency, and enables innovative solutions.

Find out more