Software-based assistance systems provide support when assembling and installing wiring connections. All the necessary data for mounting control cabinet modules, such as terminal strips, is provided as required. Manual mounting activities are also supported by smart solutions.

Mounting

Virtual assistant simplifies manual mounting

Wiring and handling made easy

Eplan Smart Wiring guides the worker through the wiring process step by step. They have an overview of everything, even without a circuit diagram. The same is true for scenarios where multiple control cabinets are wired in parallel or different colleagues work on the same project. The required wires are assembled at the Rittal Wire Terminal. Handling systems such as the Rittal assembly frame and the Smart Lifter provide support for manual activities.

Your advantages for greater efficiency:

Manufacturing and installation processes are much simpler

Easy monitoring and documentation

Convenient solutions make it easier to perform manual mounting activities

Digital data-enabled assistance systems are the key to secure and efficient assembly processes.

(Phillip Falkenhagen, Head of BO Rapid Design, Eplan)

Eplan Smart Mounting

Digital worker guidance for mounting mechanical and electrical components in the control cabinet

Workers are guided step-by-step through the manual activities and receive visual support in 3D at each step

Central order management and progress overview for workers and production management

Eplan Smart Wiring

Step-by-step guide for easy wiring without a circuit diagram

From the terminal point to the exact installation route, all the necessary information is provided in digital form – also in 3D if required

Status information facilitates project handover between different employees and enables project monitoring

Eplan eView

Digital review of circuit diagrams with redlining and greenlining

Location-independent single source of truth for defined users

Circuit diagrams are always up-to-date, even after project completion

Data security ensured by the Eplan Trust Center

Rittal assembly frames

Easy and variable fixing of mounting plates with a quick-release fastener

Minimal space requirements when not in use

Individually positionable in the workshop due to being independent from the power grid

Easy handling due to four castors including total lock function

Rittal Wire Station

Flexible and efficient use for assembly and wiring activities in the workshop

Electrically adjustable height for ergonomic work

Multiplex worktop with integrated ruler

Workstation with integrated socket strip and shadow board for Rittal tools

Rittal Smart Lifter

Easy transportation of bayed control cabinets in the workshop or at the installation site

Supports the simple mounting of bases beneath control cabinets

Flexible use for control cabinets of different depths, thanks to adjustable forks

Ergonomic lifting and lowering with a torque crank

Phoenix Contact Hand tools

Cutting, stripping, crimping, mounting, and measuring – Phoenix Contact provides you with the best hand tools for every application in electrical engineering.

Discover the high-quality processing and measuring tools from our tools product range.

As a system supplier, we have a range of products that includes standardized ferrules and connectors and crimping tools designed to work with them for reliable wire preparation.

Phoenix Contact clipx WIRE assist

The worker assistance system for efficient wire preparation

Modular workplace design, mobile work possible, and optimal positioning of tools and automatic devices

Convenient use through intuitive user interfaces and simple CAE data transfer

Process reliability through software-supported wire preparation with direct device control

Phoenix Contact labeling and application systems

For the first time ever, the THERMOMARK E SERIES marking system combines and automates several process steps in the identification process, thereby enabling a considerable increase in efficiency in this time-consuming undertaking.

Time savings of around 60% with printing and application in a single process step.

Flexible response with the modular system comprised of a standard thermal transfer printer and four applicators for different identification solutions.

Consistent digital workflows.

Easy handling and constantly high quality with the automated process.

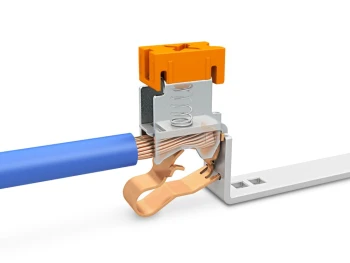

Phoenix Contact tool-free wiring

Maximum ease of use thanks to the force-saving Push-X and Push-in technology

Reduced assembly times - due to the clever spring design, direct wiring is possible without tools

High flexibility in conductor selection - with Push-X and Push-in, both rigid and flexible conductors can be wired effortlessly

Full compatibility with the CLIPLINE complete modular terminal block system enables the use of standardized accessories