All manufacturing steps are automatically derived from the information for the virtual prototype. All the necessary machine programs can be created automatically through direct communication with the Human Machine Interfaces of modern automation solutions. Manual manufacturing is also supported digitally.

Manufacturing

Digital all the way to production

From the digital twin to the real product

The digital twin provides input for manufacturing systems such as Rittal Perforex and various semi-automated machines, fully automated wire processing machines, and printing systems. Data can also be used for additional services, such as Phoenix Contact’s terminal strip service.

Your advantages for greater efficiency:

Intelligent support of manual manufacturing processes

Automation solutions for cost efficiency and high product quality

Flexible services for custom order situations

The seamless interplay between design engineering and configuration ensures simple and error-free construction of the complete enclosure.

(Thorsten Freytag, Product Manager Value Chain Digitalization, Rittal)

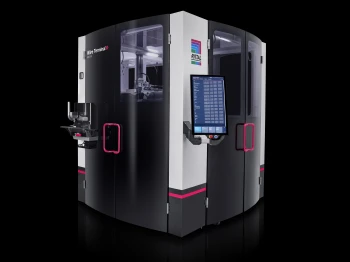

Rittal Perforex MT

Fully automated hole-drilling, thread-tapping, and milling of cut-outs and housings with the

Convenient data import of common CAD systems and planning tools such as .dxf, Eplan Pro Panel, RiPanel Processing Center and Rittal Configuration System

Rittal Perforex LC

3D-Bearbeitung von pulverbeschichteten Stahlblech- und Edelstahlgehäusen sowie Montageplatten, Türen, Seitenwänden und Dachblechen

Einfache Datenübernahme gängiger CAD Systeme und Planungstools wie .dxf, Eplan Pro Panel und Rittal Configuration System

Phoenix Contact clipx BASIC line

Modular workstation systems for control cabinet building

Individual equipment and expansion with modular, scalable accessories

Fast process optimization with increased efficiency

Ergonomic design and structured arrangement of components

Optimized for production processes in control cabinet building through years of experience in process consulting

Phoenix Contact clipx ENGINEER assemble

Worker assistance software for terminal strip assembly

Direct transfer of project data from the engineering process

Simplified presentation through step-by-step display of the process steps

Error avoidance when selecting items by controlling a pick-by-light system

Phoenix Contact marking systems

Create markings easily: whether with a laser marker, high-speed printer with UV LED technology or a thermal transfer printer

Wide range of marking technologies provide the right solution for marking terminals, wires and cables, equipment, and plants

The right solution for every application in industrial identification, thanks to various marking materials

Phoenix Contact clipx WIRE assist

The worker assistance system for efficient conductor preparation

Modular workstation design, mobile use, and optimum positioning of automatic devices, tools, and material

Convenient application with intuitive user interfaces and simple CAE data transfer

Process reliability, thanks to software-supported conductor preparation with direct device control

Phoenix Contact clipx WIRE assist Software

The necessary wiring information is exported from Eplan PRO Panel and fed into the clipx WIRE assist software.

Based on this data, the clipx WIRE assist software guides the worker through the semi-automated wire preparation process.

At the same time, the devices in the worker assistance system are controlled directly and the necessary information for further processing and wiring is displayed on the monitor.

In addition, an integrated editor function also allows data to be created or supplemented manually.

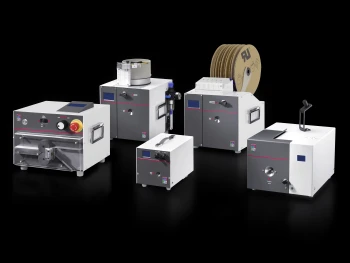

Phoenix Contact automatic devices

Cutting, stripping, and crimping: automating these steps provides cost-effective advantages, even for small and medium-sized batches

High functionality, fast setup times, and consistently high-quality results

Easy startup with Plug and Play and intuitive operation

Phoenix Contact Hand tools

Cutting, stripping, crimping, mounting, and measuring – Phoenix Contact provides you with the best hand tools for every application in electrical engineering.

Discover the high-quality processing and measuring tools from our tools product range.

As a system supplier, we have a range of products that includes standardized ferrules and connectors and crimping tools designed to work with them for reliable processing.

Rittal Cutting Terminal

Cutting centre for wiring ducts, cable duct covers and mounting rails

Smart component placement thanks to integrated component labelling

Very low waste costs thanks to waste optimisation

Reliable production control and planning reliability through the use of the RiPanel Processing Centre

Rittal busbar machining CW 120

Bending, punching, and cutting of copper and aluminum busbars

Flexible and easy handling, high bending and punching precision, efficient and ergonomic operation, easy tool change

The integral precision laser facilitates the cutting and bending process

Rittal Wire Terminal WT C

Fully automated wire end processing with ferrules

Management of up to 36 different wires and sequential or order-specific wire output in an ordering system

Full networking from the E-CAD tool through to the manufacturing processes

The assembled wires can be processed via EPLAN Smart Wiring

Rittal semi-automated machines

Assembly of wiring cables: cutting, stripping, and crimping

Pneumatically or electrically driven cable assembly

Interfaces to the PC or to CAE data in EPLAN Pro Panel (depending on the model)

Phoenix Contact marking app for smartphone and tablet

Intuitive operation: The THERMOMARK GO can be fully operated with the MARKING system app

Application Guide: with just a few clicks, get easy and efficient the right marking solution

The app is available for Android and iOS

Automatic updates: the latest software version available at any time

Guided creation of application-specific and standard-compliant labeling solutions

Phoenix Contact Wire duct and DIN rail cutters

With the profile and DIN rail cutters from Phoenix Contact, you can cut a wide variety of DIN rails and wiring ducts quickly, without much effort, and with precision.

Ensure a clean and safe work environment: Cut plastic or metal profiles without burrs.

Follow-up work, like deburring when sawing, is not necessary.