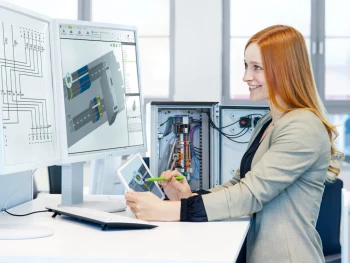

In detail engineering, digital data takes center stage in product development and production. Engineering software is used to create circuit diagrams to provide an image of the automation project. Solutions for further product planning are connected via interfaces.

Detail engineering

Digital product development

Closely interlinked engineering software

With Eplan Electric P8, circuit diagrams are created using defined item data. PROJECT complete, PLCnext Engineer, and the EPLAN platform interact via standardized interfaces such as AutomationML. The CAD data from the configuration result can be extracted directly from the Rittal Configuration System and transferred to the mechanical design.

Your advantages for greater efficiency:

Seamless communication from engineering through to manufacturing based on standardized data for individual products

Cross-solution bidirectional data exchange, based on manufacturer-neutral interfaces such as AutomationML

Digital imaging of the automation project for a transparent interdisciplinary planning process

Uniform and open data standards make it possible to seamlessly network every process stage.

(Dr. Andreas Schreiber, Vice President Industrial Cabinet Solutions, Phoenix Contact)

Eplan Data Portal

Access high-quality online product catalogs from numerous component manufacturers

Easily transfer component data to the Eplan documentation

Minimize the amount of effort required to maintain master data

The new Eplan Data Portal includes the data standard based on ECLASS

Eplan Electric P8

Consistent, seamless, and fast engineering system for configuration in electrical design

Automated reports and project documentation

Engineering information provided for downstream processes

Phoenix Contact PROJECT complete

The planning and marking software supports all phases of terminal strip configuration and provides individual and convenient process support, from electrical planning through to delivery of the finished product.

PROJECT complete comes equipped with optimized interfaces to Eplan Electric P8 / Eplan Pro Panel. With just a click of the mouse, the software imports the data from electrical planning and automatically designs the corresponding terminal strip.

Intelligent functions automate many planning steps and provide significant time savings.

Phoenix Contact clipx ENGINEER

The clipx ENGINEER engineering software makes it possible to plan and procure terminal strips, assembled mounting plates, and junction boxes more efficiently than ever, and to seamlessly transfer the data to production – at every workplace.

Create your function groups more efficiently with the use of functional engineering.

Complete your electronics planning through automation with the necessary accessories.

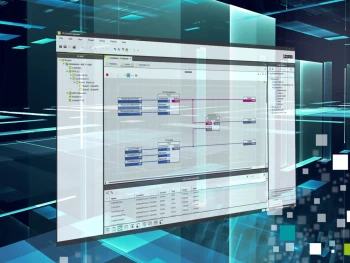

Phoenix Contact PLCnext Engineer

Engineering software platform for Phoenix Contact automation controllers.

Simplified engineering process, thanks to the use of automation modules and object-oriented programming.

Time and cost savings, thanks to fully integrated programming in a single interface.

Less work and training involved, thanks to the optimized user interface.

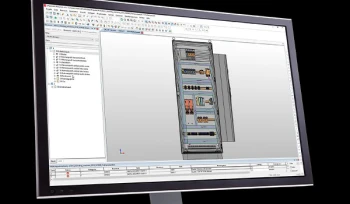

Rittal RiPanel

Easy selection of an enclosure system

Error-free accessory selection with verification checks, visual presentation and positioning in the 3D model

Add machining options incl. CAD import of customer specific cut-outs

Automatic generation of technical data and direct submission of an enquiry or order

Thermal Design Integration

Comprehensive concept consisting of digital product data, software-based configuration tools, and newly developed climate control solutions

Thermal aspects are already taken into consideration during the control cabinet planning phase

Verification of climate aspects and interactive planning of the best possible climate control solution

Eplan eBuild

Automatically create schematics based on Eplan macro technology

Design standards are available worldwide via the Eplan Cloud environment

Easily enter requirements via the self-explanatory configuration interface

Access to ready-made libraries from Phoenix Contact with the free version, Eplan eBuild Free

Getting started is possible without in-depth expert knowledge, IT or programming effort